CRANE HOOK

Crane hooks are critical components in heavy lifting equipment and are specifically designed to ensure safe and efficient material handling. Here are the key features of crane hooks used in heavy lifting Here's a breakdown of the specifications and key features that manufacturers typically provide or adhere to:

Specifications

Material

Forged Carbon Steel &

Alloy Steel

Heat Treatment: Quenched and tempered for strength and toughness

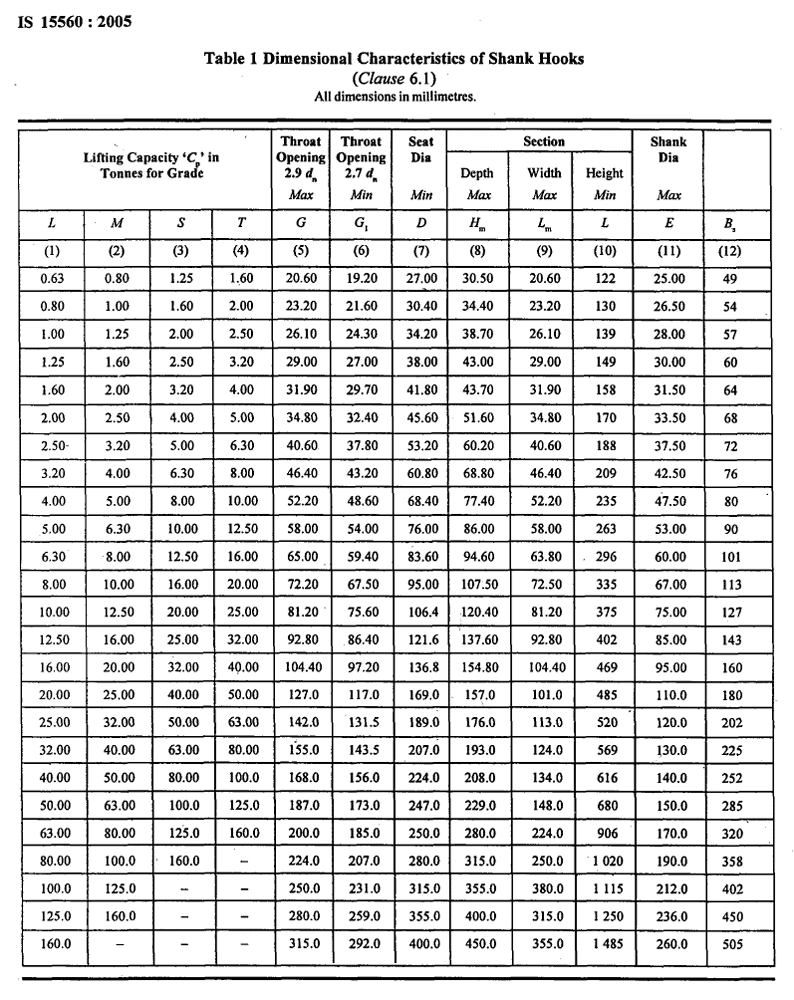

Load Capacity

Typically ranges from 1 ton to 500+ tons, depending on the hook type

Hook Types

Single Hook: For lighter or standard loads

Ramshorn (Double) Hook: For very heavy loads or equal load distribution

Clevis or Eye Hooks: Depending on the connection method

Safety Factor

Usually designed with a Safety Factor of 4:1 to 6:1, based on the Working Load Limit (WLL)

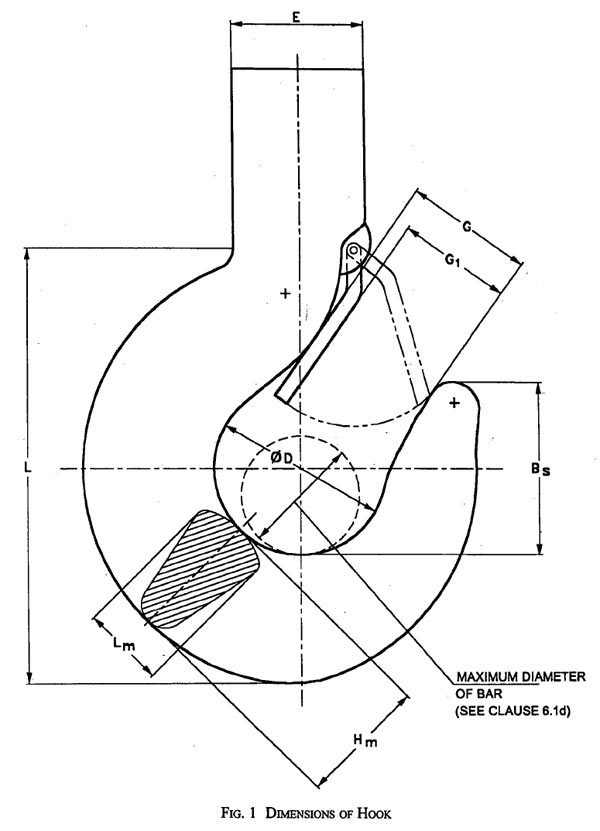

Dimensions

Throat Opening, Inside Height, Body Width, Shank Length (for shank-type hooks), Based on DIN or manufacturer-specific standards

Key Features

Latch Mechanism

Spring-loaded safety latch to prevent accidental detachment. Heavy-duty or self-locking latches for higher capacities.

Swivel Capability

Swivel hooks for rotating loads safely during lift. With or without bearing (bearing allows smooth rotation under load).

Markings

Clearly stamped with: Manufacturer name, Load rating (WLL), Serial number & Compliance standard

Wear Indicators

Wear indicators (grooves or marks) on the hook throat or body. Designed to show when the hook has worn beyond safe use.

Corrosion Resistance

Galvanized or painted surfaces for protection. Marine-grade options for offshore cranes.